Epoxy is usually a style of resin which is produced by mixing two factors jointly - a resin plus a hardener. When these two parts are mixed, a chemical response occurs, causing a strong, durable substance that may be employed for a number of purposes. Epoxy is known for its exceptional adhesion, chemical resistance, and mechanical properties, which makes it a well-liked choice for an array of industries, together with building, automotive, aerospace, and marine.

Epoxy is obtainable in many different forms, which includes liquid, paste, and good, and can be used as an adhesive, coating, or filler. It may be placed on a variety of surfaces, including metal, wood, concrete, and plastic, which makes it a flexible substance for many alternative projects. Epoxy can also be offered in a wide array of hues and finishes, making it simple to personalize to fit the particular demands of a task.

Epoxy is frequently used in combination with other supplies, including fiberglass or carbon fiber, to produce composite components which might be lightweight and strong. It can also be used to be a protecting coating for surfaces that happen to be subjected to harsh environments, like chemical spills or extreme temperatures. In general, epoxy is a flexible and durable material which includes a wide array of programs across many alternative industries.

How Epoxy is Applied

Epoxy is Utilized in a wide range of purposes, from industrial to creative. In the construction marketplace, epoxy is often used being an adhesive for bonding supplies together, for example metal to metallic or metal to concrete. It is usually used for a coating for floors and partitions to provide security towards substances, abrasion, and moisture. Within the automotive field, epoxy is utilized for bonding system panels and repairing weakened elements. It is additionally used being a protecting coating for undercarriages and also other metallic components to forestall corrosion.

In the marine sector, epoxy is useful for repairing fiberglass boats and generating tailor made components. Additionally it is made use of as a protective coating for hulls and decks to avoid h2o intrusion and destruction from marine organisms. Within the aerospace sector, epoxy is employed for bonding composite products together to make lightweight and robust constructions. Additionally it is applied to be a protecting coating for plane factors to offer resistance versus Intense temperatures and harsh environments.

Within the art globe, epoxy is used for making sculptures, jewelry, as well as other decorative goods. It might be blended with pigments together with other elements to generate exclusive types and finishes. General, epoxy is a versatile product that could be Utilized in an array of applications, from industrial to inventive.

Great things about Employing Epoxy

There are plenty of Added benefits to making use of epoxy in numerous purposes. On the list of key advantages of epoxy is its excellent adhesion Houses. When appropriately used, epoxy varieties a strong bond While using the substrate, making a strong and prolonged-lasting link. This can make it a great option for programs wherever powerful adhesion is necessary, like in development and automotive industries.

Another advantage of applying epoxy is its chemical resistance. Epoxy is highly proof against a wide range of chemicals, like acids, solvents, and oils. This can make it a perfect choice for apps where by exposure to harsh chemical compounds is widespread, including in industrial configurations or maritime environments.

Epoxy also provides superb mechanical Homes, which include high strength and toughness. This makes it a great option for apps where by longevity and impact resistance are important, including while in the aerospace sector or for developing tailor made pieces during the maritime field.

In combination with its Actual physical Attributes, epoxy also provides aesthetic Added benefits. It is on the market in a wide array of colours and finishes, which makes it easy to customize to suit the particular wants of a project. This can make it a really perfect option for programs the place visual appeal is very important, including within the artwork entire world or for decorative coatings in household or business settings.

In general, epoxy presents an array of benefits which make it a perfect option for a number of applications throughout numerous industries.

Differing kinds of Epoxy

There are lots of different types of epoxy readily available available on the market, each with its possess unique Homes and applications. One particular common sort of epoxy is named "epoxy resin," that's a transparent liquid which might be mixed with various additives to develop customized formulations. Epoxy resin is usually useful for casting and encapsulating programs, like developing attractive goods or encapsulating Digital components.

Guidelines for Working with Epoxy

Working with epoxy needs thorough notice to detail and correct approach to guarantee thriving results. A single critical suggestion for dealing with epoxy will be to diligently Adhere to the company's Guidance for mixing the resin and hardener. Good mixing is important for achieving the specified Attributes of your epoxy and making sure a solid bond.

Basic safety Safeguards when Employing Epoxy

Although epoxy gives numerous Advantages for numerous purposes, it's important to take good basic safety safeguards when working with this product. One particular crucial safety precaution when applying epoxy is to operate inside a perfectly-ventilated place in order to avoid inhaling fumes from your resin and hardener. Epoxy fumes can be annoying towards the respiratory procedure and should cause dizziness or nausea if inhaled in significant concentrations.

Environmental Effect of Epoxy

Though epoxy delivers many Positive aspects for numerous apps, it's important to consider its environmental affect. One prospective environmental issue with epoxy is its manufacturing course of action, which may entail using chemicals which can be destructive towards the natural environment Otherwise correctly managed. It is necessary for manufacturers to consider suitable steps to attenuate the environmental influence of producing epoxy by way of liable sourcing of Uncooked materials and waste management methods.

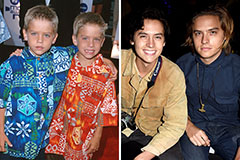

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!